DINOSAURS OF

PATAGONIA

By

GOTA

Gota, is a company from Cordoba Argentina, which specializes in the manufacture of special projects.

The company faces challenges of designing and manufacturing personalized projects, with limited deadlines, for which it has an interdisciplinary team of designers from different areas, technicians, installers and its own state-of-the-art machinery.

Being part of that team, I was able to live the experience of materializing projects like the one I show you below:

BRIEF:

Date: March 2022

Project: Traveling exhibition "Dinosaurs of Patagonia" from the Egidio Feruglio Paleontological Museum (MEF). Conceptual development and technical constructive resolutions of scenographic support elements fully developed in house.

Conceptual Design: Gota.

Construction: Gota.

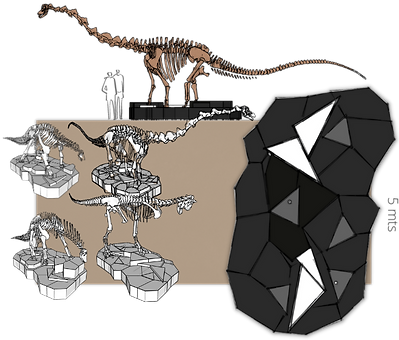

Objective: Design and construction of support bases for fossil replicas, as well as elements of stage lighting, signage and posters with information about the sample. For the project to be successful, the entire sample had to be designed and manufactured within a time limit of 40 days.

Challenge: The entire sample was manufactured in Córdoba, Argentina and shipped to Australia. Therefore, there were very demanding conditions regarding times, volume and weight of all the components to be able to be loaded in already limited containers. Most of the elements had to be systems that traveled disassembled and be designed to be easily assembled

MY ROLE

In this project I was responsible for developing the bases for various fossils:

Design of support furniture and scenographic covering, with lighting and indicative information for dinosaur fossils.

Design of concept and manufacturing solutions

Constructive technical communication, CAD/CAM modeling, monitoring and permanent dialogue with the blacksmithing, carpentry, electricity and installation team, quality control of the pieces.

THE PROJECT

-

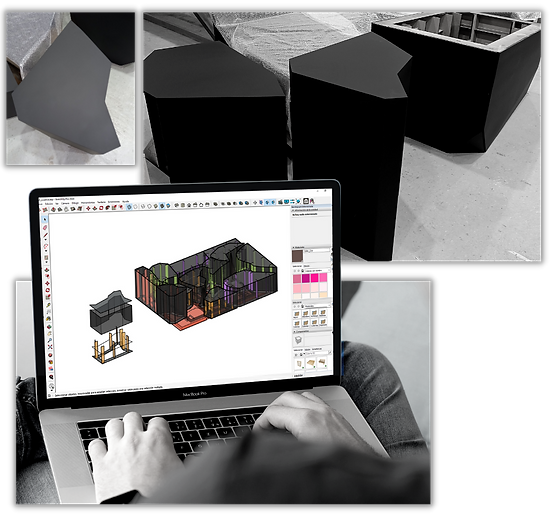

The predominant materials were 9, 12 and 15 mm thick mdf plates, acrylic and some pieces of sheet metal that allowed dynamic links and joints to be made.

-

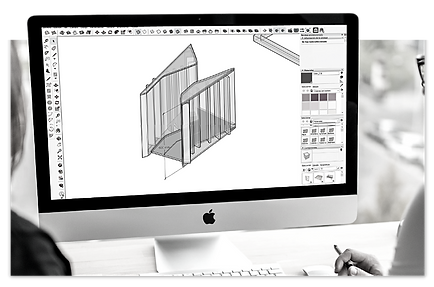

For the conceptual and detailed development of the elements, the software used was Sketchup for 3D modeling and Adobe Illustrator for the generation of CAM files, as well as construction plans.

We sought to develop geometric elements that would conceptualize rocks or natural geographical features.

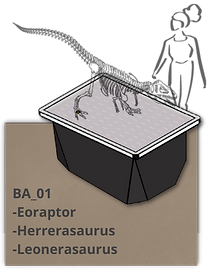

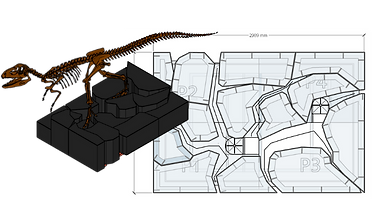

BA_01

-Eoraptor

-Herrerasaurus

-Leonerasaurus

CONCEPT

The item represents a giant Ipad that "projects a 3D fossil".

BA_01

-Eoraptor

-Herrerasaurus

-Leonerasaurus

DEVELOPMENT

MDF rib system, cladding with nailed and glued plates. Pieces cut with laser technology.

Communication and coding of parts for cutting and assembly.

A coding system was developed to achieve an exact classification that allowed the assembly and fixing of each piece as indicated in the plan and 3D model.

BA_01

-Eoraptor

-Herrerasaurus

-Leonerasaurus

FINALS

BA_02

-Condoraptor

-Eobelosaurus

CONCEPT

This piece sought to represent the image of cracks with lava and fire.

BA_02

-Condoraptor

-Eobelosaurus

DEVELOPMENT

The rapid prototyping process allowed to solve the final lighting effect.

A model was created that simulated the joint of two modules, to verify how much the fossil was going to be illuminated, as well as, if the desired color effect was achieved. At this stage, the permanent collaboration with carpenters, electricians and painters made it possible to validate the design of the pieces.

Given the limited times, to carry out technical drawings, a simple system with colors, images and part codes had to be found, in order to be able to communicate to the production team how each part should be assembled.

BA_02

-Condoraptor

-Eobelosaurus

FINALS

BA_03

-Amargosaurus

-Carnotasaurus

-Neunquensaurus

-Brachitacheloplan

CONCEPT

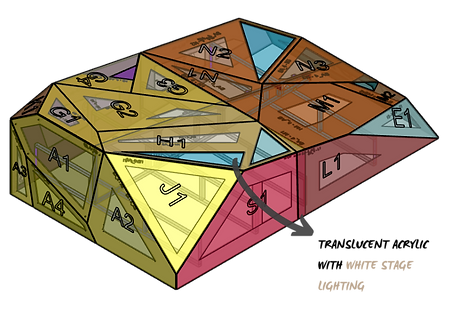

Continuing with the concept of ordered "chaos", it was designed so that everything fits together perfectly.

BA_03

-Amargosaurus

-Carnotasaurus

-Neunquensaurus

-Brachitacheloplan

DEVELOPMENT

Challenge, larger elements, need to reduce volume, match various structures.

Four identical pieces of furniture were developed in their constructive conception. The structures functioned as an independent coating to the metal supports of the fossils and each one had some "adjustment" element that allowed to vary heights and also to give each one a distinctive touch so that they do not look exactly the same.

The triangular lighting modules were an important part of these elements since they gave the scenic touch to highlight the fossils. They also served as independent adjustment elements that allowed installers to correct possible defects in the installation.

BA_03

-Amargosaurus

-Carnotasaurus

-Neunquensaurus

-Brachitacheloplan

FINALS

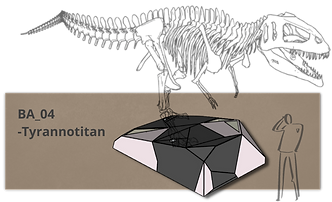

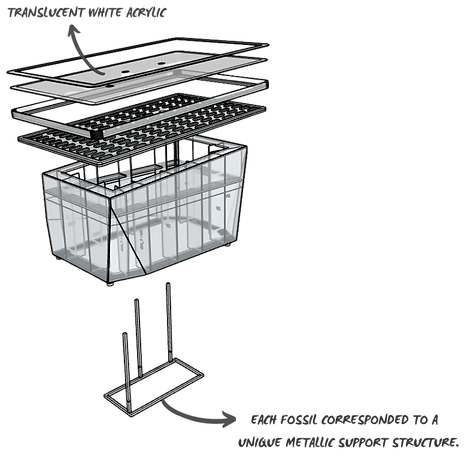

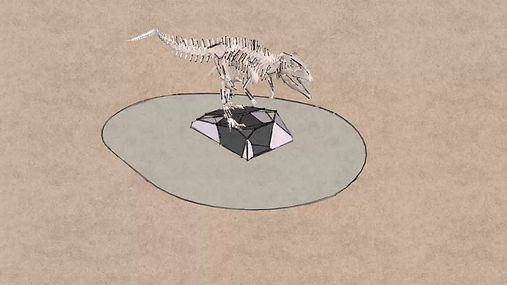

BA_04

-Tyrannotitan

CONCEPT

This furniture was a volume with flat pieces and a simple assembly system.

BA_04

-Tyrannotitan

DEVELOPMENT

Consisting of an internal structure with a removable pipe, which functioned as a backbone, and with a lining of plates fixed by means of screws. This system allowed the pieces to occupy very little volume when loading them into the shipping container.

Internal structure plus plate lining.

BA_04

-Tyrannotitan

FINALS