ICEBERG FURNITURE GOOGLE OFFICES

By

GOTA

Gota, is a company from Cordoba Argentina, which specializes in the manufacture of special projects.

The company faces challenges of designing and manufacturing personalized projects, with limited deadlines, for which it has an interdisciplinary team of designers from different areas, technicians, installers and its own state-of-the-art machinery.

Being part of that team, I was able to live the experience of materializing projects like the one I show you below:

BRIEF:

Date: January 2022

Project: Design development in technical and construction detail of furniture for Google headquarters in Bs. As., Argentina.

Designers: 3G offices.

Construction: Gota Arquigrafia.

Objective: Modular system design, ready to assemble at destination, lightweight, resistant to transfer.

Challenge: Complex morphology with predefined installation position, irregular, large, monolithic, walkable, with integrated lighting

MY ROLE

In this project I was the main designer, in charge of:

Design of technical solutions, technical construction communication, CAD/CAM modeling, monitoring and permanent communication with production personnel, quality control of the parts, in charge of installation on site.

Although every project in the company is carried out with the participation and consultation of the entire design and production team, which makes it possible to meet each challenge

THE PROJECT

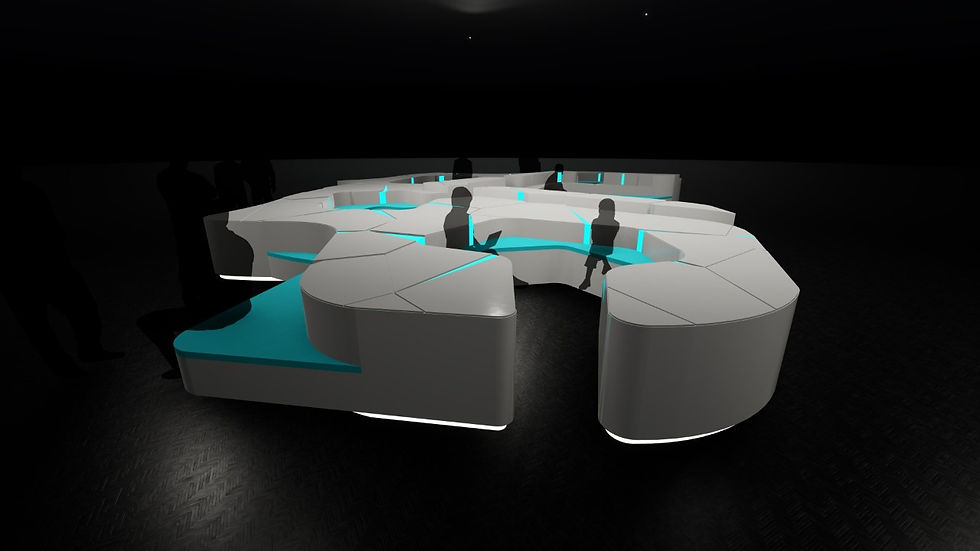

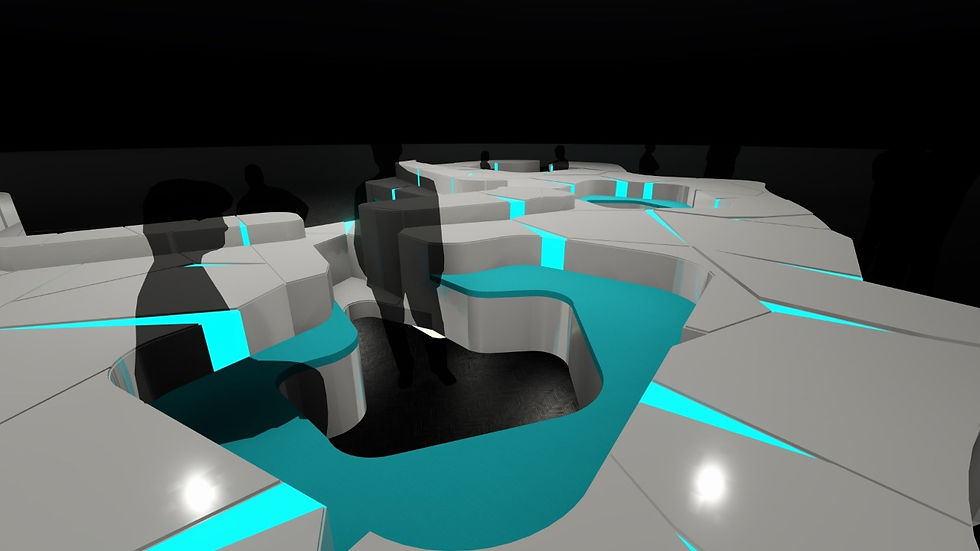

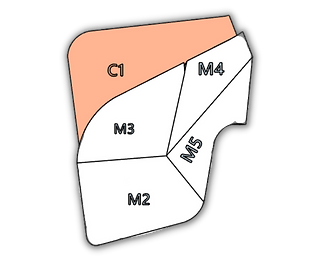

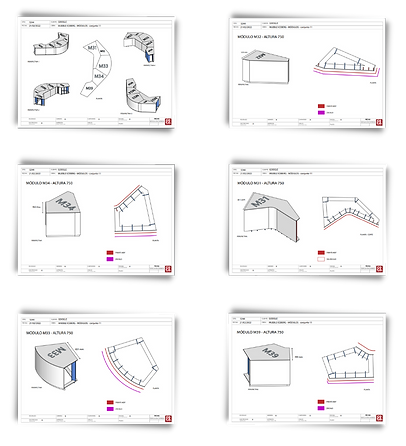

The geometry was divided into modules of three different heights.

-

The joint between the modules was accentuated by rounding the edges to conceptualize the breaking of the pieces of ice.

-

For the union, sheet metal links were designed that, by means of screws, allowed the position of the modules to be adjusted.

-

Software used Sketchup for modeling and Adobe Illustrator for generating CAM files.

98

COMPONENTS

CONSTRUCTION SYSTEM

A system of standardized and interlocking vertical ribs was designed.

For the coating, a grooving system to be able to bend the mdf plates.

MODEL OF CHECK OF MATERIALS, FINISHES AND LIGHTING

CODING METHOD

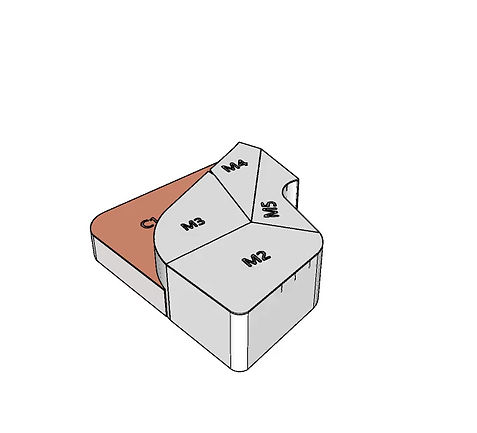

Being so many pieces, modules and complex morphologies, what would be a great puzzle.

A coding system was developed to achieve a classification and production monitoring of the elements

Each piece of each module had its identification laser engraved.

LABORATORY

During the design process, several ideas were tested that allowed better decisions to be made.

Rapid prototypes were developed to validate the lighting proposal, resistance of materials and aesthetic finishes.

10 modules led lighting, resolved with neon led "iceblue" and frosted acrylic which generated a "thaw" effect

TECHNICAL COMMUNICATION

Design validation with clients and constructive information for production teams.

FABRICATION PROCESS

Laser cut

Preparation of CAD files. 3 for each module, sent to the system for cutting 12mm mdf plates. Standard vertical rib cutting for large quantities.

01

Plate grooving

Grooving 7mm deep in 9mm mdf boards on a horizontal cutting saw.

02

Module assembly

Gluing and nailing of curved geometry cladding plate following the morphology of laser cut covers. Installation of skirting boards in 3mm mdf

03

Position checking and matchup adjustment

The modules were presented by strategic zones and manual adjustments were made in complex encounters

04

Painting process

Placement of plastic putty in joints, sanding and painting in a pressurized paint booth with high-transit glossy polyurethane.

05

TRANSFER TO WORKPLACE

Great challenge, since multiple truck trips were made on roads in poor condition.

It required a good packaging to protect the structures, since the strength was achieved once the entire set was assembled.