MACHINE DESIGN

Academic project

BRIEF:

Date: April 2020

Project: Identify a stage of the production process in a small or medium gastronomic industry and generate a Design solution applying Pneumatics concepts to optimize that process.

Designers: Martín Juarez - Margarita Aostri.

Academic subject: Technology and its applications III - Profesores DI. Gastón Vocos - Ing. Pablo Gonzales.

Company: LDM- Factory of milanese soybeans and chickpeas. For more than 20 years, LDM has provided products of excellent quality and high nutritional value. Beginning in the interior of Córdoba, with a sustained growth rate and consolidating itself as a model Food Industrial SME in its sector..

Challenge: Incursion from scratch in the Pneumatic concept and in the development of machinery for industrial food production.

MY ROLE

-

Conditioning factors

-

Problems and sub problems

-

Design assumptions

-

Design program

-

Proposals and alternatives

-

Selection criteria and weighting table

-

Product structure

-

Solution development and design

-

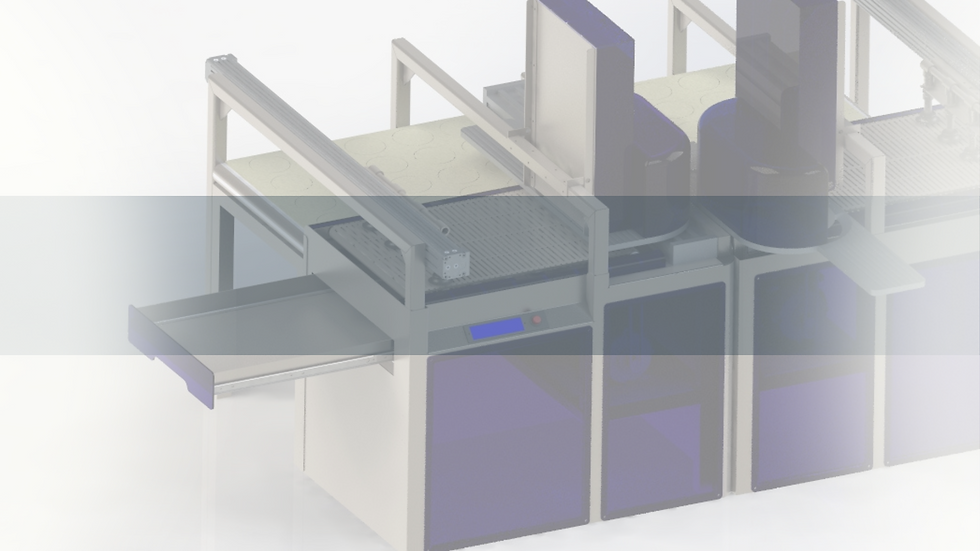

Virtual model

-

Technical memory

-

Panels and presentation

THE COMPANY

LDM, was born in 1997, in the town of Colonia Caroya, Córdoba. The first customers were families and neighboring pantries.

Some recognized clients are:

-

Mariano Max

-

Libertad

-

Buenos días

-

Walmart

-

Catering companies

Since 1997 They have been dedicated to the Manufacture and distribution of Soy and Chickpea Milanese.

Number of employees: Five.

Its direct and most important clients are small and medium-sized stores, but it also distributes in large retail areas.

THE PRODUCT

Soy and Chickpea Milanese, stuffed or unstuffed.

Circular morphology, approximately 100 mm in diameter, 10 mm thick without filling and 15 mm with filling. Rough uncooked breadcrumb color texture. Weight per unit approximately 60 gr.

The main consumers are students.

40% of consumers are in Córdoba Capital.

In Carlos Paz, Punilla, Sierras Chicas, Jesús María and

Colonia Caroya the remaining 60% of consumers.

DESIGN PROBLEM

The following general objectives were established.

-

Design a machine to automate the filling process of Soy and Chickpea Milanese.

-

Standardize the Milanese filling process.

-

Optimize filling times in the production process.

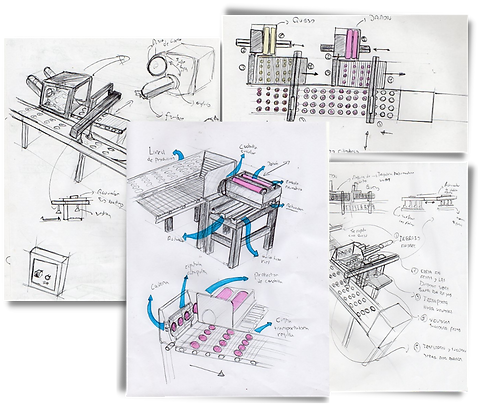

PROPOSAL STAGE

In this stage the content of the design program is defined.

It begins with the design of possible solutions to the problems detected during the investigation carried out.

DESIGN PROPOSAL

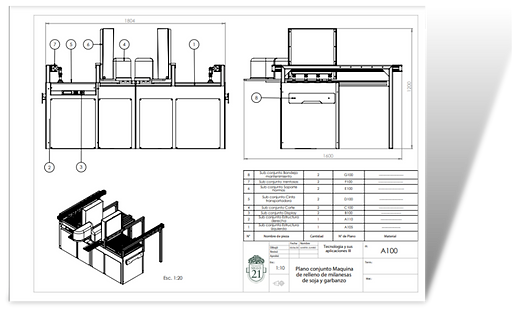

Device for automating the filling of soybean and chickpea milaneses.

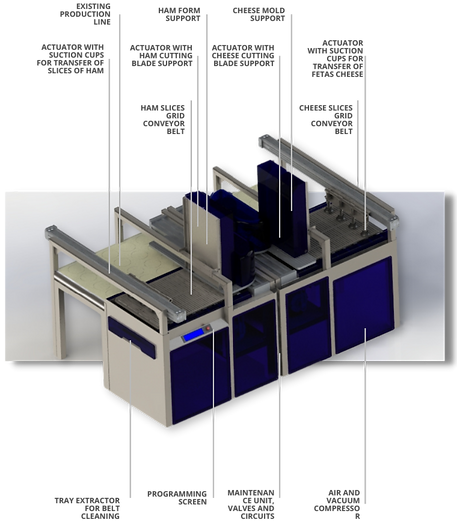

The device is composed of electro-pneumatic systems that allow the automation of the filling of the milanesas in the production line.

Designed with galvanized steel pipe structures, stainless steel casings and trays (suitable for the food industry), as well as transparent acrylic covers that allow visualizing the operation of subsystems and facilitating proper hygiene of machinery in general.

DETAILS STAGES AND MECHANISMS

Next, the explanation of the process, its operation, components and designed features will be broken down by stages.

The explanation will be divided into the following process:

-

Raw material placement

-

Slices cut

-

Separation of slices

-

Placing slices on the production line

OPERATING PROCESS

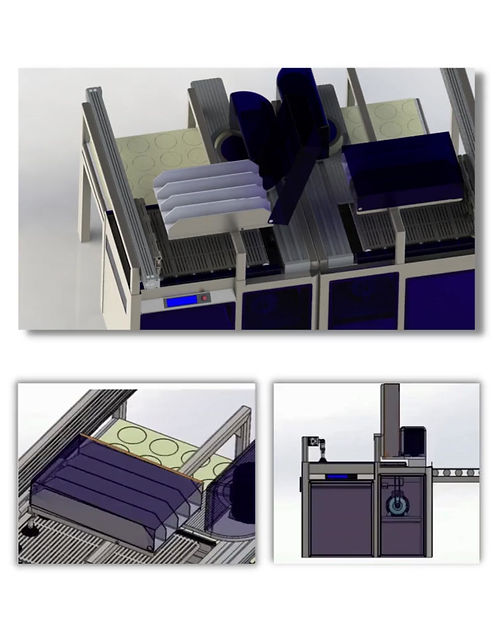

Placement of lasts

The machinery has two folding supports prepared for the placement of four ham lasts and four cheese lasts with a diameter of 60 mm and a length of up to 500 mm. They have a translucent acrylic lid that protects the lasts from dirt and contains them for greater precision and safety when cutting.

01

-

Support base built in a combination of acrylic and 1mm folded stainless steel sheet, without edges, with rounded edges and edges.

-

Being retractable facilitates the placement of the last, without the operator having to make great efforts.

-

Between the four lasts it must resist 16 kg of at the moment of rotation.

Vertical cutting position

02

Slicing process

The cutting process is made up of two rotating circular blades of 250 mm in diameter, positioned in a "mirror" manner, activated by two 1/3 hp single-phase motors. The blades and their respective motors are positioned on aluminum structures,

designed to be mobilized by two double-acting linear pneumatic actuators with guides and carriage. These devices allow the movement of both structures simultaneously along the lasts so that the filleting of the ham and cheese can be carried out.

03

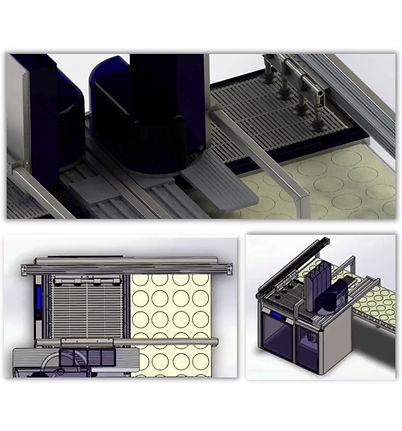

Slice separation

Once the slices have been cut by the cutting disc in thicknesses of 1mm, they fall onto a mesh conveyor belt. Thanks to the arrangement of the molds, the slices fall one next to the other with the exact separation they need to be correctly placed on the pre-marked dough.

The conveyor belt is mobilized by an electric motor

direct current with magnetic brake, which allows the belt to stop for a few seconds while waiting for the four slices to be cut. Once the four lasts have been sectioned, the tape advances a few millimeters to go towards the suction cups that will be responsible for placing the filling on the dough.

04

Placing slices on the production line

After passing through the mesh conveyor belt, the slices reach the suction cup kit, where they are simultaneously sucked and mobilized by a double-acting actuator, which transports and positions the slices on the dough in the production line.

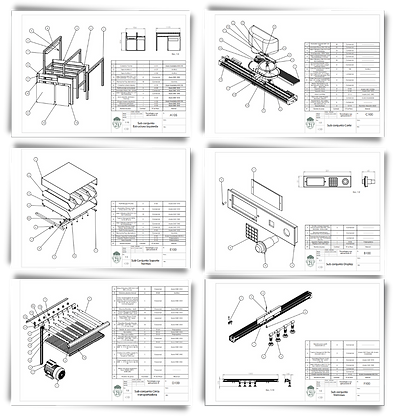

TECHNICAL COMMUNICATION

Development of technical plans according to the IRAM standard for the production of the developed parts

FLUID CALCULATIONS

Pneumatic actuators and suction cups circuit diagram

Part of the project was to calculate and diagram in detail the layout of the selected valves and components for the operation of double-acting actuators and suction cups.

THE FINAL RESULT