VISA FRONTDESK

HEAD OFFICES ARGENTINA

By

GOTA

Gota, is a company from Cordoba Argentina, which specializes in the manufacture of special projects.

The company faces challenges of designing and manufacturing personalized projects, with limited deadlines, for which it has an interdisciplinary team of designers from different areas, technicians, installers and its own state-of-the-art machinery.

Being part of that team, I was able to live the experience of materializing projects like the one I show you below:

BRIEF:

Date: June 2021

Project: Design development in technical and construction detail of Frontesk for the main hall of Visa's central offices in Puerto Madero, Bs. As., Argentina.

Conceptual Design: Emanuel Garabello - AFT Architects.

Construction: Gota Arquigrafia.

Objective: Design and construction of a monolithic irregular geometric morphology, more than 5 meters long, with corian plates, without details of visible joints, ready to assemble at destination, resistant to transfer from the laboratory to the final place (800 km away).

Challenge: Complex morphology, heavy, fragile and expensive material, with predefined installation position, irregular geometry, large, monolithic, with integrated lighting.

MY ROLE

In this project I was the main designer, in charge of:

Design of manufacturing solutions, technical construction communication, CAD/CAM modeling, monitoring and permanent communication with the Blacksmithing, Carpentry, Electricity and Installation team, quality control of the pieces.

Although every project in the company is carried out with the participation and consultation of the entire design and production team, which makes it possible to meet each challenge.

THE PROJECT

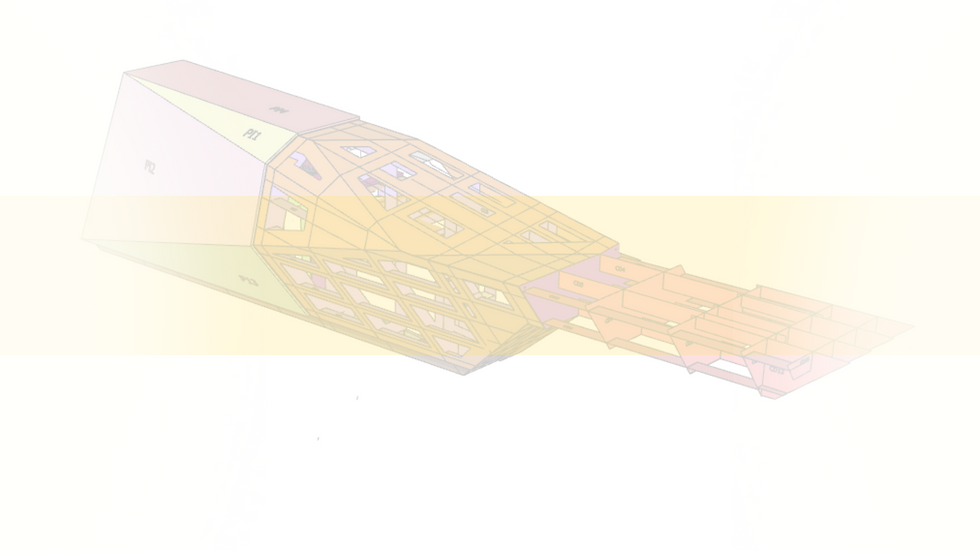

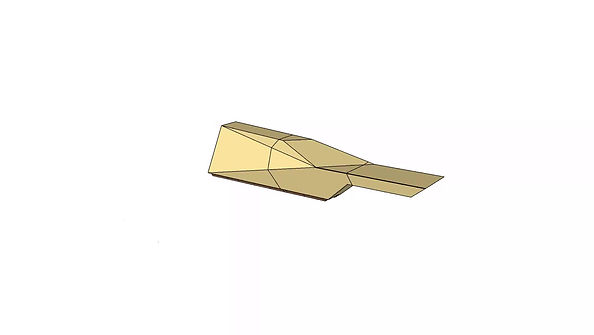

Metal interior structure and corian exterior cladding.

-

A welded sheet metal structure was developed as a support skeleton for the final corian coating.

-

In turn, the skeleton was divided into three modules, which are linked together with union bolts and preset positioners for easy installation on site.

-

Software used Sketchup and Solidworks for modeling and Adobe Illustrator for generation of CAM files and Technical drawings.

CONSTRUCTION SYSTEM

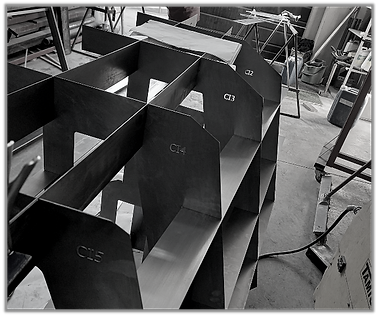

Insert design for laser cut sheet metal frames.

To achieve the morphology, a system of inserts was designed that allowed the fit in the exact position of each rib.

Model check of the construction process projected for the final model

With so many pieces being similar to each other, it would be a great puzzle for the welder.

A coding system was developed to achieve an exact classification that allowed the assembly and fixing of each piece as indicated in the plan and 3D model.

CODING METHOD

Each piece of each module had its identification laser engraved.

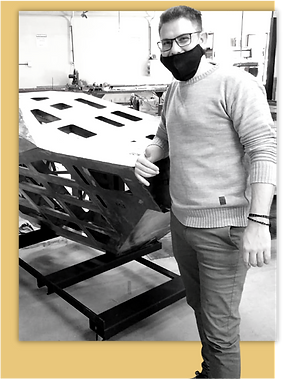

LABORATORY

The prototyping and design process merged with the interdisciplinary work of the technicians.

To minimize the possibility of errors in cutting corian plates (due to its high cost), it was decided to simulate each piece of cladding with mdf of the same thickness. Each retouched piece was then relieved, to produce the necessary modifications for the final cut files.

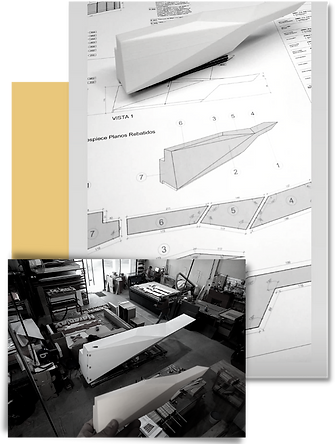

TECHNICAL COMMUNICATION

Design validation with clients and constructive information for production teams.

CAD visualization devices were used in this project to share assembly information with the blacksmith team.

FABRICATION PROCESS

Laser cut

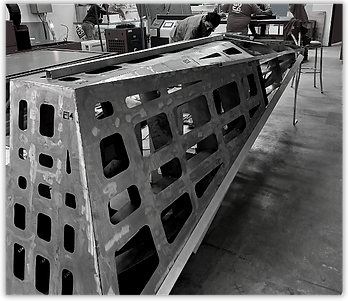

Preparation of CAM files. The frames for the skeleton were cut from 18-gauge sheet metal. While the joint ends between the 3 modules were made from 1/8-gauge sheet metal.

01

Frame assembly

The sheet metal ribs were embedded with each other with male/female slots - Vertical/horizontal and after being fixed with spot welds to avoid deformations.

02

Veneer coating

The frames were unified with a superficial skin of 20-gauge sheet metal, which would later function as an area for applying glue to support the final coating.

03

Coating layout

It was completely covered with mdf boards in order to determine the final cuts, position and angles of the Corian coating boards.

04

Painting of "skeleton"

After finishing with the layout with MDF plates, the test pieces were disassembled and the three modules that made up the furniture were painted with polyurethane paint to protect the metal from corrosion.

05

Final covering in Corian

Placement of Corian plates, finishing of joints between pieces with special fixing paste and surface polishing to achieve a final mirror finish.

06

TRANSFER TO WORKPLACE

Great challenge, since the three structures had to travel 800 km to their installation site

It required good packaging to protect the structures, since the union of the corian plates with the metallic structure was done by glue, which meant that the union could be affected by movement.

THE FINAL RESULT